If your processing facility isn’t utilizing a high-quality color sorting machine, you may be missing out on an indispensable piece of technology that...

Gravity Separators and Destoners for Grain and Seed Products

Confidently separate and remove impure or defective products with intelligent density separation technology that accurately separates Impurities from good products that have similar shape and color but different densities.

-

Cimbria Gravity Separator

-

Vacuum Destoner

-

Pressurized Destoner

Cimbria Gravity Separator

The Cimbria gravity separator is used to separate any kind of kernel or granular product with nearly the same size and shape, but with different densities between good products and foreign material or damaged kernels.

Gravity Separator Features

- Feeding device to facilitate consistent product flow

- Easy to operate

- Full or partial dust hood

- Lightweight aluminum decks

- Accurate separation of light and heavy product

- Stone trap

- Stratification pins

Gravity Separator Benefits

重力表是一个添加水平的准确性d quality of your finished products and should only be used with pre-cleaned products. It is ideal for complex separating applications such as identifying grown-out, damaged cereals, broken cocoa beans from cocoa germs, green coffee beans from unshelled beans, ergot from rye, nuts from shells, sticks, etc.

Material Types

- Corn

- Cocoa Beans

- Dry Beans

- Green Coffee

- Nuts

- Pulses

- Rapeseed

- Seeds

- Tea

- Vegetable Seeds

- Wheat

Vacuum Destoner

Cimbria vacuum style destoners separate granular materials into two fractions using a combination of deck movement and airflow through the deck. Vacuum destoners are compact and dust-tight. They find their application mainly in the elimination of heavy impurities, such as stones, metal, and glass from coffee, grain, pulses, and other crops that are harvested close to the ground.

Destoner Features

- Single fan produces both process air and dust aspiration

- 100% dust-tight

- Adjustable deck Inclination and air volume

- Self-regulating inlet-shoe

- Reverse airflow system on the stone outlet, saves good product

- Multiple wire mesh types are available

Destoner Benefits

Vacuum destoners are energy efficient, requiring only one fan for both process air and dust aspiration. They are easy to operate and 100% dust-tight due to the negative pressure in the machine.

Material Types

- Dry Beans

- Green or Roasted Coffee

- Paddy or White Rice

- Pulses

- Sesame

- Soybeans

- Wheat

Pressurized Destoner

Cimbria pressurized destoners use radial fans to produce a very uniform airflow through the mesh deck to lift light material while the heavy material sinks to the deck surface. Pressurized destoners offer higher capacity than their vacuum style counterparts and are very precise in the removal of heavy impurities, such as stones, metal, and glass from coffee, grain, pulses, and other crops that are harvested close to the ground.

Destoner Features

- Decks with dedicated pre-bins

- Adjustable feed rate

- High-pressure fans with step-less adjustment of process air

- Reverse airflow system on the stone outlet, saves good product

- High capacity

- Multiple wire mesh types are available

Destoner Benefits

The pressurized destoner offers high capacity and is easy to adjust. It Is also very precise in its separations due to the advanced pressurized air system. It’s ideal for food processing and milling applications that handle coffee, oats, grain, or pulses.

Material Types

- Dry Beans

- Green or Roasted Coffee

- Oats

- Paddy or White Rice

- Pulses

- Sesame

- Soybeans

- Wheat

Let's Talk

We want to help you find the right fit for your next density separating system. Reach out to our team to discuss your needs so we can help you discover the right equipment for you.

Talk to a RepResources

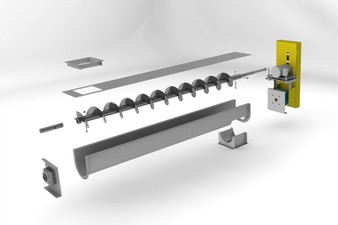

Screw conveyors, also known as auger conveyors, are used to efficiently transport dry bulk materials such as grains, flours, animal feed,...

Contact Us

We’re here to answer any questions or discuss how we can help you with your next project or equipment needs.