Screw conveyors, also known as auger conveyors, are used to efficiently transport dry bulk materials such as grains, flours, animal feed,...

Belts Conveyors, Chain Conveyors, Screw Conveyors and More for Bulk Materials

运输散装materials with more speed and efficiency for increased productivity and profit.

-

Belt Conveyor

-

Vibrating Conveyor

-

Chain Conveyor

-

Screw Conveyor

-

Pneumatic Conveyor

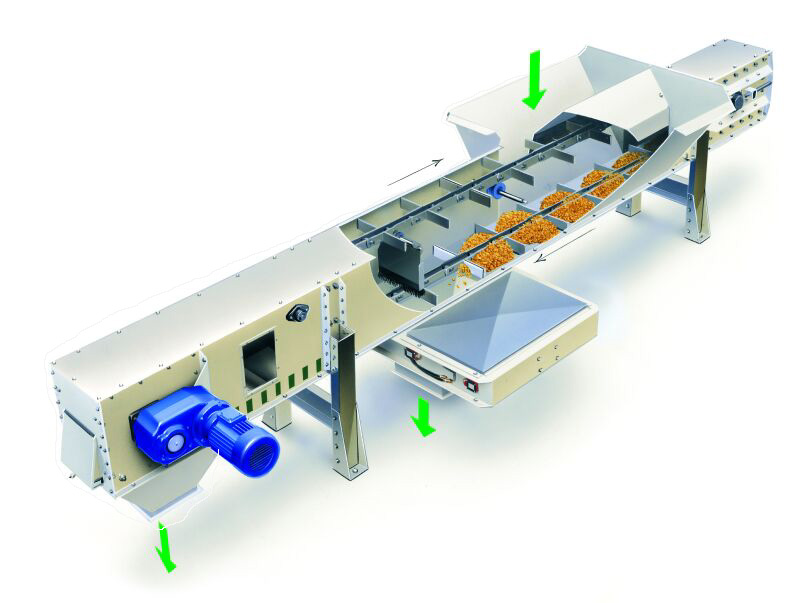

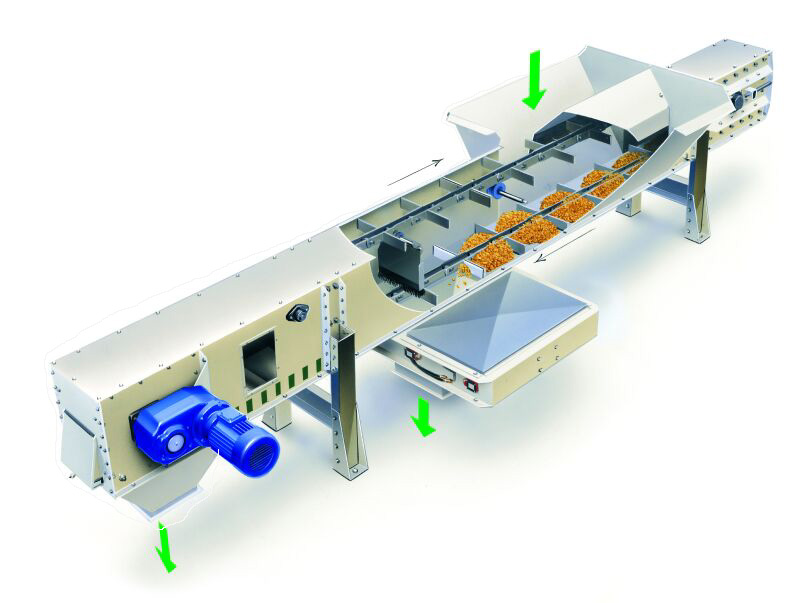

Belt Conveyor

Belt conveyors are a gentle horizontal conveying solution for granular bulk products like grain, pellets, and seed. The belt conveyors are designed with a modular system so that can be manufactured to exact length requirements and with optional features to provide a complete solution. This self-emptying system requires minimal energy consumption and is very resistant to wear, making it a long-lasting solution.

Belt Conveyor Features and Accessories

- Modular Structure

- 滑块床或辊床styles

- High-Quality belt choices Including oil resistant and food grade

- Optional covers

- Belt Misalignment Detector

- Emergency Stop Switch

- Overspeed protection

Belt Conveyor Benefits

This reliable conveyor type requires minimal maintenance and energy consumption, which translates to maximum uptime and increased profits. Its versatility of handling materials makes it the perfect solutions for almost any conveyor application.

Material Types

- Minerals

- Seed

- Granules

- Maize

- 白米

- Green Coffee

- Sunflower

- Grain

- Pellets

- Fertilizers

- Wood Chips

- Ear corn

Vibrating Conveyor

Vibrating Conveyors are specifically designed for shorter, horizontal transportation of grain or similar products. Often used at receiving, these units can be built very robustly to handle the heavy loads typically associated with the rigors and demands associated with this process.

Vibrating Conveyor Features and Accessories

- Self-Emptying

- Self-Cleaning

- Output of 10-35 tons wheat/hour

- Electromagnetic, Eccentric, or Inertia Drive System for Gentle Conveyance

- Segmentation Capabilities to Convey Multiple Products at Same Time

- Four Length Options Available

- Simple Construction and Minimal Maintenance

- Easy-to-Replace Wearing Parts

Vibrating Conveyor Benefits

This conveyor system is ideal for short distance horizontal conveying and is a reliable and cost-effective solution. It has versatile application capabilities and can be fed or discharged at multiple locations with guaranteed clean out between runs.

Material Types

- Minerals

- Seed

- Granules

- Maize

- 白米

- Green Coffee

- Sunflower

- Grain

- Pellets

- Fertilizers

- Wood Chips

- Maize Cobs

Chain Conveyor

Chain conveyor systems offer an optimum way to convey grain, and other bulk materials horizontally or at an incline. Modular in design, these types of chain conveyor systems can be easily supplied for a particular length and with proper planning, can be added to in the future.

Chain Conveyor Features and Accessories

- Completely Closed, Dustproof Transport

- Modular Structure

- Well Suited for Outdoor Installations

- Galvanized Steel Sheets

- Conveyor Chain Manufactured with Special Steel and Welded Flights

Chain Conveyor Benefits

Chain conveyors are suitable for a wide range of application in silo/storage plants, processing plants, and bulk intake applications. The chain conveyors are sturdy and reliable and require minimal maintenance or downtime, which increases productivity and profitability.

Material Types

- Minerals

- Seed

- Granules

- Maize

- 白米

- Green Coffee

- Sunflower

- Grain

- Pellets

- Fertilizers

- Wood Chips

- Powders

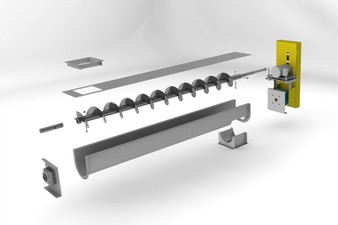

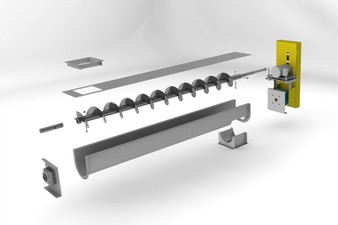

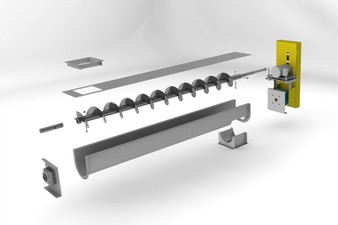

Screw Conveyor

Screw conveyors are designed for inclined and or horizontal conveying a range of dry bulk materials such as grain, flour, feed, wood pellets, or plastic granulates. These machines are highly customizable in order to suit your application needs and capacity requirements.

Screw Conveyor Features and Accessories

- Completely Closed, Dustproof Transport

- Modular Structure

- Option for Painted, Hot Dipped Galvanized, or Stainless-Steel Version

- Multiple Inlets and Outlets

- Multiple flight options Including: variable pitch, tapered, paddle flight and ribbon flight

Screw Conveyor Benefits

The screw conveying system is highly efficient and handles a variety of industrial and agricultural bulk materials. The sturdy and durable equipment can handle 24/7 usage and requires low maintenance which increases productivity and profitably.

Material Types

- Minerals

- Granules

- Cement

- Fly Ash

- Flour

- Animal Feed

- Grain

- Pellets

- Fertilizers

- Wood Chips

- Sugar

- Starch

- Powders

Pneumatic Conveyor

Pneumatic conveyors transport products like flour, grass seed, feed and food ingredients, resins, cement, or powders through a pressurized or vacuum type system. Pneumatic conveying systems offer a long-lasting, trouble-free alternative to some mechanical conveying solutions.

Pneumatic Conveyor Features and Accessories

- Air Generation Device

- Air Lock

- Material to Air Metering Device

- Material to Air Separation Device

- Conveyance Medium (tubing, piping, or hose)

Pneumatic Conveyor Benefits

The pneumatic conveyor is easy to install and has flexible routing, making it compatible with various processing plant layouts and parameters. It is entirely self-contained machine and requires very low maintenance.

Material Types

- Minerals

- Cement

- Flour

- Grass Seed

- Animal Feed

- Powders

Let's Talk

We want to help you find the right fit for your next conveyor system. Reach out to our team to discuss your needs so we can help you discover the right equipment for you.

Talk to a RepResources

A leading producer of machinery for oat, rice, and specialty milling, Schule has been providing quality milling equipment since 1892. By partnering...

Contact Us

We’re here to answer any questions or discuss how we can help you with your next project or equipment needs.