If your processing facility isn’t utilizing a high-quality color sorting machine, you may be missing out on an indispensable piece of technology that...

Automatic Form, Fill, and Seal Baggers

The most efficient and effective way to package chemicals, minerals, fertilizers, and cement at high speeds and with accurate bag weights.

-

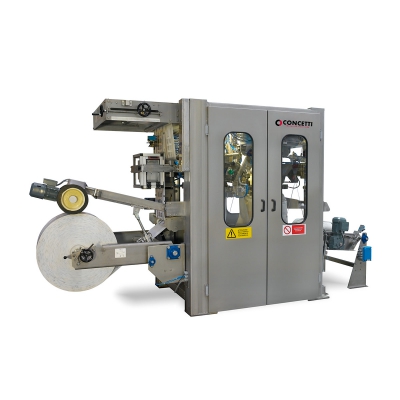

FFS-E Form, Fill & Seal Bagger

-

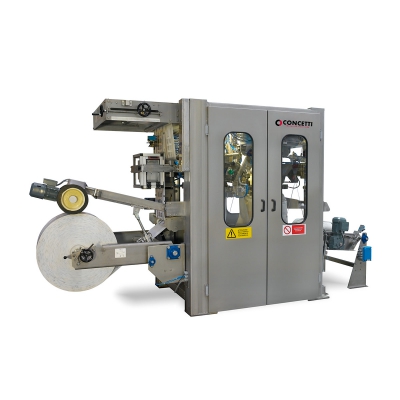

Continua Form, Fill & Seal Baggers

-

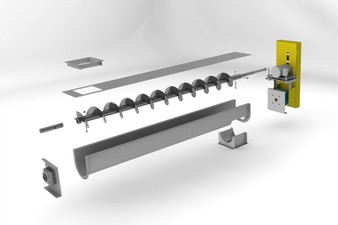

Continua FFS Bagger for Fine Powders

FFS-E Form, Fill & Seal Bagger

The FFS-E is a high-speed form, fill and seal bagger capable of producing more than 2,000 bags per hour. It is designed to handle free-flowing products including pellets and granules in FFS bags ranging from 10 to 110 pounds. Built specifically for use in hazardous locations and available constructed out of stainless steel for corrosive environments.

技术特点

- Bag Weights: 10 to 110 lbs.

- Fully Automatic, recipe-driven changeover

- Rate: up to 2,000 bags/hour

- Form bags from high-capacity, tubular reels

- Three Operating Stations:

- Bag formation station

- Filling station

- Sealing station

Key Benefits

The FFS-E is a highly productive machine with an extremely small footprint that is built to withstand corrosion. It has an easy-to-use control panel and is simple to clean. This intelligent machine can change reels quickly and safely and keep production running with a minimal interruption between products.

Material Types

- Free-Flowing Products

- Chemicals

- Fertilizer

- Minerals

Continua Form, Fill & Seal Baggers

The Continua series of FFS baggers by Concetti are designed to offer flexibility for a wide range of granular and powdered products. Five models range in bagging speeds from 600 to 1,800 bags per hour into FFS bags weighing between 10 and 100 pounds to match any application and budget.

技术特点

- Bag Weights: 10 to 110 lbs.

- Fully Automatic, recipe-driven changeover

- Rate: 600-1,800 bags/hour

- Form bags from high-capacity, tubular reels

- Three Operating Stations:

- Bag formation station

- Filling station

- Sealing station

Key Benefits

The automation and speed of this equipment make the form, fill, and seal process extremely efficient. It will minimize downtime during format changes and maximize productivity. Designed specifically to handle challenging powders that aerate or fluidize when handled.

Material Types

- Granular products

- Powdered products

Continua FFS Bagger for Fine Powders

The multi-station Continua Form, Fill and Seal bagger is specifically designed for bagging extremely fine powders like fine premix and cement into hermetically sealed PE bags. Advanced features like the dust-tight spout, de-aeration probes, bag top air removal, and seal cleaning and cooling make this form, fill, and seal bagger an ideal choice for bagging fine powders.

技术特点

- Bag Weights: 10 to 110 lbs.

- Fully Automatic, recipe-driven changeover

- Rate: up to 800 bags/hour

- Built with stainless steel for durability

- Six linear bagging positions specially designed for handling fine powders

- Deaeration probes for reducing product volume

- Dust-tight filling spout and bag holder

- Bag top air removal

- Seal cleaning and cooling

Key Benefits

Material Types

- Extremely Fine Powders

- Premixes

- Cement

Let's Talk

We want to help you find the right fit for your next form, fill, and seal system. Reach out to our team to discuss your needs so we can help you discover the right equipment for you.

Talk to a RepResources

Screw conveyors, also known as auger conveyors, are used to efficiently transport dry bulk materials such as grains, flours, animal feed,...

Contact Us

We’re here to answer any questions or discuss how we can help you with your next project or equipment needs.