Screw conveyors, also known as auger conveyors, are used to efficiently transport dry bulk materials such as grains, flours, animal feed,...

Bagging Scales and Weighing Systems

Ensure the accuracy of your packaged goods with Concetti’s precise weighing and feeding systems.

-

Gravity Feed Bagging Scales

-

Belt Feed Bagging Scales

-

Screw Feed Bagging Scales

-

Double Feed Bagging Scales

Gravity Feed Bagging Scales

Concetti’s gravity feed bagging scales are ideal for free- to semi-free flowing products like seeds, whole grains, and cereals. These machines are built to improve the speed of your production lines by being simple, accurate, and efficient. There are models available to suit your material type, preferred bagging rates (up to 2,000 bags per hour), and various bag types.

Technical Features

- 重Range: 10 to 110 lbs. (5 to 50 kg)

- Rate: Up to 2,000 bags per hour

- Installed Power: 0.5kW

- Compressed-Air Consumption: 4.5 cu. ft. / bag

- Optional brushless motors for enhanced accuracy

- Control electronics can memorize up to 32 programs dedicated to various products

Key Benefits

The high-tech electronic control system of the Concetti gravity feeding scale ensures maximum precision when weighing your products. This machine can be configured to suit your specific needs and can connect seamlessly with the rest of your packaging line equipment and is easy to clean and maintain.

Material Types

自由半自由流动的材料:

- Granular

- Coarse

- Pellets

- Free-flowing powder

- Granular + Fine Powder

Belt Feed Bagging Scales

The belt feed bagging scale system operates by filling the weighing container via a belt conveyor. This type of weighing system is optimal for medium-flowing products including pellets, granules, flakes, fibrous materials, and products with gentle handling requirements. Concetti’s precise weighing system is due to the advanced technology integrated within the equipment and enables a simple, accurate, and user-friendly experience.

Technical Features

- 重Range: 10 to 110 lbs. (5 to 50 kg)

- Rate: Up to 1,500 bags per hour

- Installed Power: 1.5kW

- Compressed-Air Consumption: 2 cu. ft. / bag

- Control electronics can memorize up to 32 programs dedicated to various products

Key Benefits

Belt feeders are key for applications requiring versatility to handle a wide variety of products like animal feeds and they are also perfect for products that require gentle handling. The advanced PLC control system and precise product regulating gate make these belt feed scales highly accurate. When part of a complete installation, this machine can communicate with other machines downstream for seamless packaging line flow.

Material Types

Medium-Flowing Products like:

- Pellets

- Flakes

- Granulated/Powder Mixes

- Fibrous materials

- Products that Require Gentle Handling

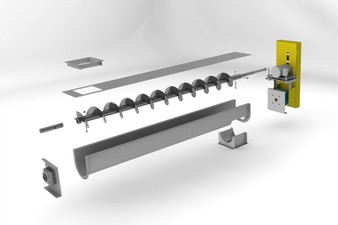

Screw Feed Bagging Scales

The Concetti Screw Feed Bagging Scales are ideal for the powders, especially difficult powders like those that flow either very well or those that can be difficult to move. The screws are fully contained in a housing that prevents dust from escaping during product transport and ensures highly accurate weights.

Technical Features

- 重Range: 10 to 110 lbs. (5 to 50 kg)

- Rate: Up to 1,500 bags per hour

- Installed Power: 7kW

- Compressed-Air Consumption: 4 cu. ft. / bag

- Control electronics can memorize up to 32

programs dedicated to various products - Optional Features: single screw, double

screws, inclined screws, and self-cleaning

systems

Key Benefits

This screw-feed weigher makes handling less free-flowing products much more efficient and streamlined by preventing dust from escaping and measuring with maximum precision. There are many options to customize this machinery to suit your needs including automatic systems for cleaning parts in contact with products, removable screws to facilitate cleaning, and adjustable configurations to meet your operations’ requirements.

Material Types

Non-Free-Flowing Products like:

- Fine powders

- Free-flowing (Fluidized) powders

- Granular / Powder Mixes

- Difficult powders

Double Feed Bagging Scales

双尺度设计specifically to handle and weigh different products that cannot be cross-contaminated or products that have very different types of flow. This double-feed weigher can combine any two feed systems depending on your products and needs saving space and money.

Technical Features

- 重Range: 5 to 50 kg

- Rate: Up to 1500 weighments/h with gravity-feed systems

- Up to 900 weighments/h with belt-feed systems

- Up to 700 weighments/h with screw-feed systems

- Control electronics can memorize up to 32 programs dedicated to various products

Key Benefits

The double feed bagging scale ensures all your products are handled according to their characteristics which guarantees accurate filling for each product. It also minimizes cross-contamination points throughout the bagging system, reducing clean-out points.

Material Types

Combination of Free- to Non-Free Flowing Products like:

- Fine powder

- Free-flowing powder

- Difficult powders

- Granular

- Granular / Powder mixes

- Coarse

- Flakes

- Pellets

- Cubes

- Fibrous materials

Let's Talk

We want to help you find the right fit for your next bagging scale and weighing system. Reach out to our team to discuss your needs so we can help you discover the right equipment for you.

Talk to a RepResources

A leading producer of machinery for oat, rice, and specialty milling, Schule has been providing quality milling equipment since 1892. By partnering...

Contact Us

We’re here to answer any questions or discuss how we can help you with your next project or equipment needs.