McKilllip Seeds had outgrown their aging cleaning line and were looking for ways to improve the quality of their seed, a hallmark of their North...

Seed Facilities

Cultivate the Toughest Seeds for Crop Growers

All plant life begins as a fragile seed, which must be handled with meticulous care to reward us with high-yielding crops. From receiving through warehousing, each step of the seed conditioning process is critical to preserving the ability to germinate. Bratney designs, builds, and equips seed facilities with next-level innovation and technology so you can carefully clean, sort, treat, and package your seeds with ease and efficiency.

Discover Your Best-Fit Solution with Our Consultative Approach

We are inspired by solving your unique challenges and bringing you closer to your business goals. That’s why we take a deep look at your current plant processes and develop an innovative solution tailored to your business.

Enhance Plant Performance with Premium Equipment and Automation

Improving sustainability, efficiency, and safety comes down to the right technology. Although technology and equipment can never replace generations of growing practices and knowledge, they can enhance the way your valuable products are handled, cleaned, processed, and packaged.

Gain Continuous Support and Partnership

We deeply value building long-lasting relationships with our customers. Bratney always stands behind the services we provide and the equipment we supply, so whenever you need us, we’ll be there. That includes maintenance, repairs, equipment training, parts inventory and any other way we can support you.

Cimbria Pre-Cleaner

Remove large foreign material to protect downstream equipment and prepare product for precision cleaning steps.

Cimbria Super-Cleaner

Precision cleaning step to remove over and under sized kernels along with unique aspiration system to remove low density foreign materials.

Cimbria Indents

Length separation step to remove any remaining sticks, stems and pods.

Cimbria Cleaner

"2nd cleaning" high-quality screening to remove split kernels and small fines.

Cimbria重力表

Density separation step to remove low-density split and broken kernels as well disease and insect damaged kernels - simple to operate with honeycomb deck for even air distribution and fans that move with the deck.

Cimbria SEA Color Sorter

Optical sorting for precise removal of the smallest defects as well as removal of off color or incorrectly sized kernels.

Color Sorter Rerun Conveyer

2nd pass color sorting of first round rejects to reclaim any good product caught in first pass rejects.

Cimbria Treating & Coating System

Batch or continuously treating systems and drying conveyors for pulse seed producers.

Enclosed Truck Receiving Lane

Cimbria Pre-Cleaner

Remove large foreign material to protect downstream equipment and prepare product for precision cleaning steps.

Cimbria Super-Cleaner

Precision cleaning step to remove over and under sized kernels along with unique aspiration system to remove low density foreign materials.

Cimbria Indents

Length separation step to remove any remaining sticks, stems and pods.

Cimbria Cleaner

"2nd cleaning" high-quality screening to remove split kernels and small fines.

Cimbria重力表

Density separation step to remove low-density split and broken kernels as well disease and insect damaged kernels - simple to operate with honeycomb deck for even air distribution and fans that move with the deck.

Cimbria SEA Color Sorter

Optical sorting for precise removal of the smallest defects as well as removal of off color or incorrectly sized kernels.

Color Sorter Rerun Conveyer

2nd pass color sorting of first round rejects to reclaim any good product caught in first pass rejects.

Cimbria Treating & Coating System

Batch or continuously treating systems and drying conveyors for pulse seed producers.

Looking for seed conditioning or packaging equipment?

Click through the crop selection below to see our recommended equipment solution for your crops.

Tackle your next project with us.

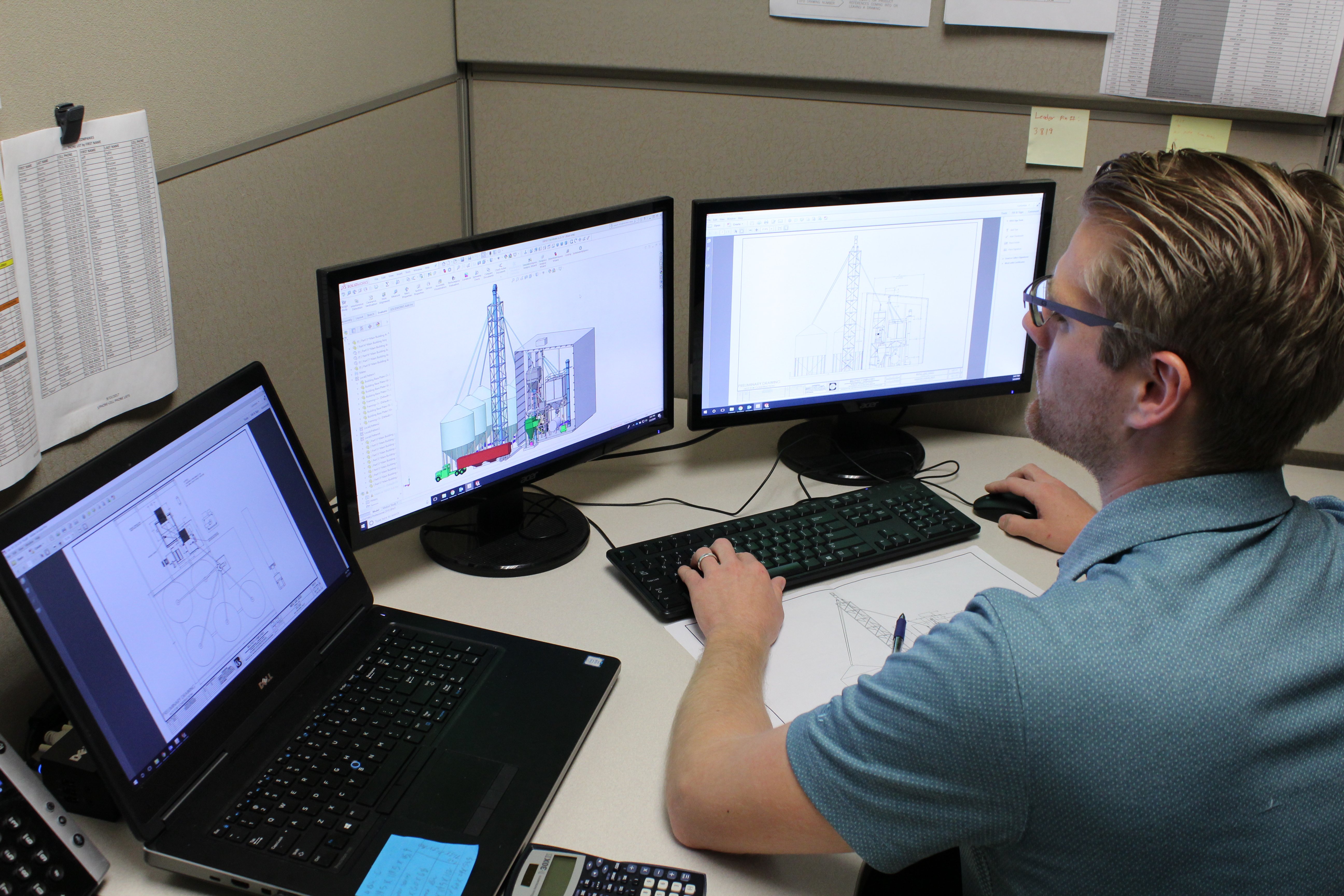

Whether you’re building an entirely new facility or enhancing your existing facility, Bratney can help. We equip you with our expert engineers, designers, construction personnel, and sales and support staff to help you discover innovative solutions that improve your production process and your bottom line.

View All Services

Process Design & Engineering

Start from scratch or improve your process with our process engineering team. We design for your materials and requirements, and create the most efficient, cost-effective processing plant.

Sample Testing & Process Flow Validation

Send us samples of your materials and our process engineers will study your samples, test them In our lab and recommend the right equipment solution to ensure your materials flow thru the plant, meet capacity specifications and do so with the most efficient process.

建筑和制造

Our construction team collaborates closely with you and our design engineers to flawlessly execute the construction of your plant and fabricate any structures to increase safety, improve performance, and build the facility that you want.

Equipment Selection, Installation & Training

选择正确的装备ipment is easy with Bratney. Our years of experience help us identify the exact equipment for your requirements, install it properly, and train your team how to use it safely and effectively.

Maintenance & Repair

Our promise to you is that we always stand by what we sell. If any equipment needs maintenance or repair, we send out our skilled technicians to handle it right away and minimize downtime.

Parts & Screens

We have a skilled, in-house team of customer service technicians ready to take care of your equipment parts and screen needs. With inhouse screen manufacturing and a significant inventory of spare parts, this team can supply the parts you need and respond to your needs immediately.

See Our Work in Action

Bratney's expertise in seed cleaning, sorting and sizing was awarded a design, procure, install contract to clean and size multiple species of...

Contact Us

Get in touch with our team about your next project! We are eager to share our 50 years of industry expertise with you to take your seed processing facility to the next level of efficiency, safety, and quality.