Edible Bean Processing Plant

When an edible bean producer from the upper Midwest found themselves with a new opportunity to expand their business by growing and processing food grade soybeans, they turned to Bratney to handle the project. The volume they anticipated warranted the construction of a new processing and packaging line on a green field site.

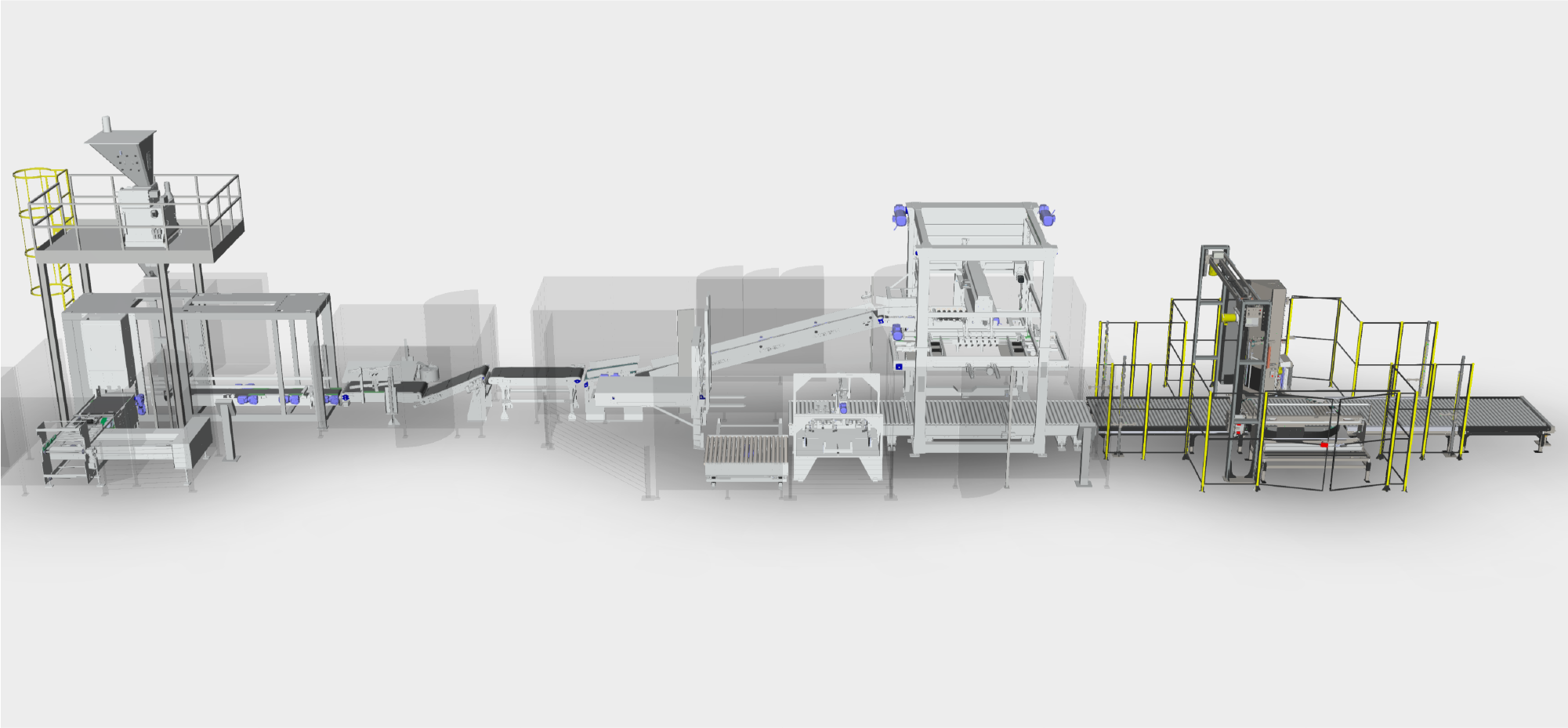

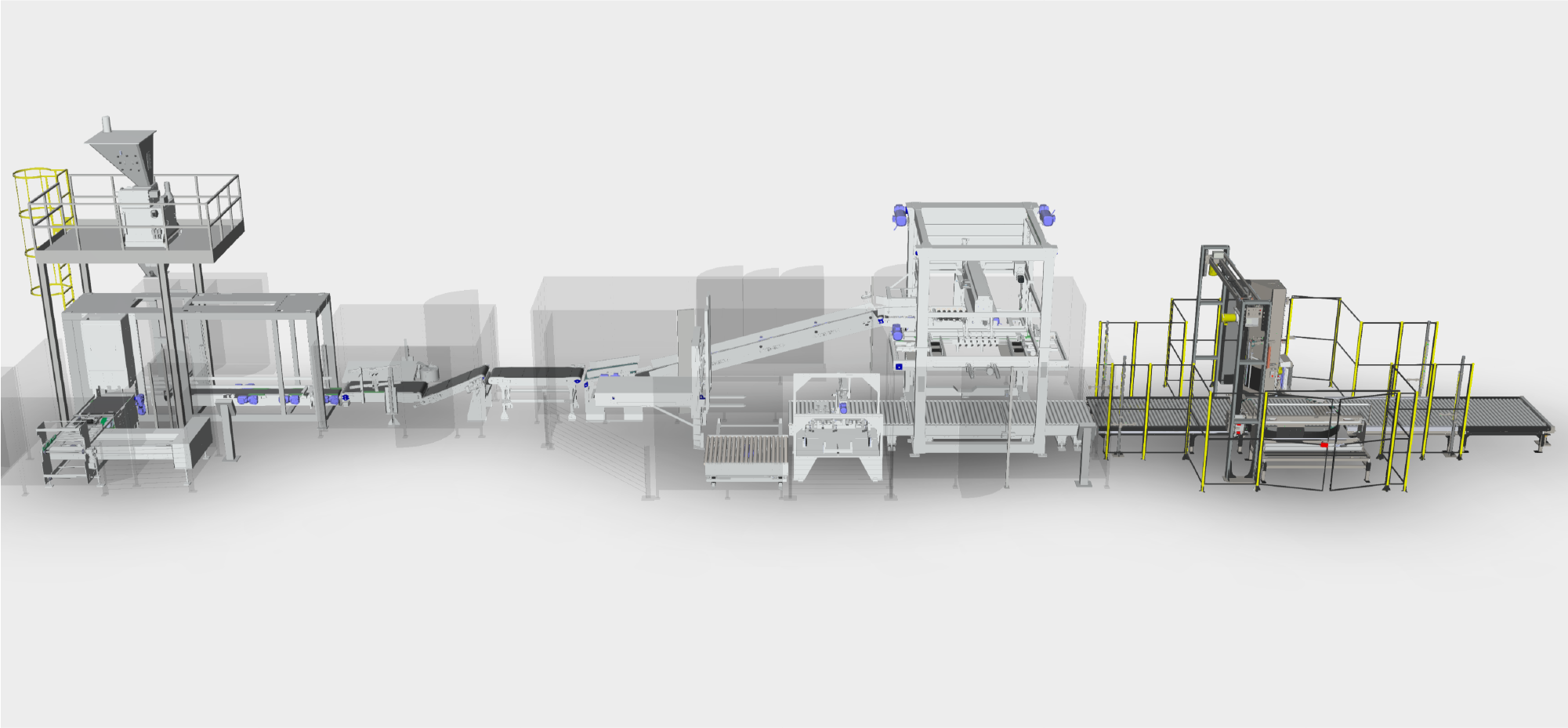

Process Flow Model

Cimbria Pre-Cleaner

Remove large foreign material to protect downstream equipment and prepare product for precision cleaning steps.

Cimbria Super-Cleaner

Precision cleaning step to remove over and under sized kernels along with unique aspiration system to remove low density foreign materials.

Cimbria Indents

Length separation step to remove any remaining sticks, stems and pods.

Cimbria Cleaner

2nd cleaning high-quality screening to remove split kernels and small fines.

Cimbria重力表

Density separation step to remove low-density split and broken kernels as well disease and insect damaged kernels - simple to operate with honeycomb deck for even air distribution and fans that move with the deck.

Cimbria SEA Color Sorter

Optical sorting for precise removal of the smallest defects as well as removal of off color or incorrectly sized kernels.

Color Sorter Rerun Conveyer

2nd pass color sorting of first round rejects to reclaim any good product caught in first pass rejects.

Cimbria Treating & Coating System

Batch or continuously treating systems and drying conveyors for seed producers.

Enclosed Truck Receiving Lane

Cimbria Pre-Cleaner

Remove large foreign material to protect downstream equipment and prepare product for precision cleaning steps.

Cimbria Super-Cleaner

Precision cleaning step to remove over and under sized kernels along with unique aspiration system to remove low density foreign materials.

Cimbria Indents

Length separation step to remove any remaining sticks, stems and pods.

Cimbria Cleaner

2nd cleaning high-quality screening to remove split kernels and small fines.

Cimbria重力表

Density separation step to remove low-density split and broken kernels as well disease and insect damaged kernels - simple to operate with honeycomb deck for even air distribution and fans that move with the deck.

Cimbria SEA Color Sorter

Optical sorting for precise removal of the smallest defects as well as removal of off color or incorrectly sized kernels.

Color Sorter Rerun Conveyer

2nd pass color sorting of first round rejects to reclaim any good product caught in first pass rejects.

Cimbria Treating & Coating System

Batch or continuously treating systems and drying conveyors for seed producers.

Automated Bagging, Palletizing & Stretch Wrapping

High-Speed Bagging Scales

Concetti automatic bagging scales are accurate to 1/10th of a pound on 50 lb. bags and include multiple feeder options to match product handling needs.

Automatic Stretch Wrapper

Automated stretch wrapping systems provide load security and protect bags during shipping.

Integrated Bag Inspection Equipment

Fully integrated check-weighers, metal detectors, x-ray systems with automatic bag reject conveyors.

Robotic Palletizing System

Concetti hybrid-robot palletizer includes robot end tooling to build overlapping layers along with layer squaring and layer compressions to build tight, square pallets.

Automatic, Open-Mouth Bagging Machine

Concetti high-speed, automatic bagging machine with bag spout designed to fill flat and gusseted bags made of any type of material including porous poly.

High-Speed Bagging Scales

Concetti automatic bagging scales are accurate to 1/10th of a pound on 50 lb. bags and include multiple feeder options to match product handling needs.

Automatic Stretch Wrapper

Automated stretch wrapping systems provide load security and protect bags during shipping.

Integrated Bag Inspection Equipment

Fully integrated check-weighers, metal detectors, x-ray systems with automatic bag reject conveyors.

Robotic Palletizing System

Concetti hybrid-robot palletizer includes robot end tooling to build overlapping layers along with layer squaring and layer compressions to build tight, square pallets.

Automatic, Open-Mouth Bagging Machine

Concetti high-speed, automatic bagging machine with bag spout designed to fill flat and gusseted bags made of any type of material including porous poly.

Project Scope

process engineering

facility design

project management

millwright services

equipment selection

equipment installation

control specifications and sequencing

facility startup and commissioning

operator training

Project Details

processing and packaging line design and general arrangement drawings illustrating building size and location on a green field site

4,000 bushel per hour enclosed receiving, sampling and bulk load out building attached to main processing building

receiving pit integrated into truck scale allowing efficient weigh in and weigh out

processing tower for up to 400 bushel per hour of edible soybeans and rye

external storage bins with let down ladders, aeration and ability to load out trucks without re-elevating out of spec product

internal storage bins to hold finished product for inspection and certification by the USGA - bins feed any combination of bulk load out system, bulk bagging system or open mouth bagging system

pneumatic finished product transfer for gentle handling

warehouse with packaging area and interior offices

in-floor heat in processing and packaging plant

filtered air from processing and packaging area returned to the building to maintain comfortable working temperatures

despite weather delays from challenging winter conditions and a wet spring the project was completed on time

screenings and off grade product could be stored separately to optimize the value of these by products

real-time weighing on bulk truck load out – highly efficient and accurate process kept the truck in one location and allowed weight ticket to be printed on demand

Equipment Solutions

Heavy duty vibratory conveyor gently conveys fragile product at receiving

Gentle handling bucket and continuous cup elevators

Inline, multi-pass aspirator to remove foreign material at receiving, prior to storage

Let down ladders in each storage and surge bin

Cimbria Precision Cleaner

Installation of customer provided destoner and shape separation equipment

Multi lane vibratory conveyor used to transfer product from one machine to the next

- Cimbria color sorters

Fully automated packaging and palletizing system

All conveyors and elevators supplied with access and cleanout features to ensure no cross contamination

Dust control system

Gallery

Other Services

Contact Us

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.